Cov khoom

-

NiNb Nickle Niobium tus tswv hlau NiNb60 NiNb65 NiNb75 hlau

Siv rau kev ntxiv cov superalloys nickel, cov alloys tshwj xeeb, cov hlau tshwj xeeb, thiab lwm yam khoom siv casting alloying

-

99.0% Tungsten seem

Hauv kev lag luam tungsten niaj hnub no, ib lub cim tseem ceeb los ntsuas cov thev naus laus zis, qhov loj me thiab kev sib tw ntawm cov tuam txhab tungsten yog seb lub tuam txhab puas tuaj yeem rov qab tau thiab siv cov peev txheej tungsten theem nrab uas tsis ua rau ib puag ncig puas tsuaj. Tsis tas li ntawd, piv nrog cov tungsten concentrate, cov ntsiab lus tungsten ntawm cov khib nyiab tungsten siab thiab kev rov qab tau yooj yim, yog li kev rov ua dua tungsten tau dhau los ua qhov tseem ceeb ntawm kev lag luam tungsten.

-

CHROMIUM CHROME HLAU NQI CR

Melting point: 1857 ± 20 ° C

Kub taw tes: 2672 ° C

Qhov Ceev: 7.19g/cm³

Qhov hnyav ntawm cov molecular sib piv: 51.996

CAS:7440-47-3

EINECS:231-157-5

-

High Purity Ferro Niobium Hauv Tshuag

Ferro Niobium Pob 65

FeNb ferro niobium (Nb: 50% ~ 70%).

Qhov loj ntawm cov khoom me me: 10-50 hli & 50 mesh.60mesh… 325mesh

-

Cobalt hlau, Cobalt cathode

1. Cov mis tshuaj molecular: Co

2. Qhov hnyav ntawm cov khoom: 58.93

3.CAS No.: 7440-48-4

4. Kev huv: 99.95% feeb

5. Kev Khaws Cia: Nws yuav tsum khaws cia rau hauv qhov chaw txias, cua nkag, qhuav thiab huv si.

Cobalt cathode: Hlau xim grey nyiaj. Tawv thiab yooj yim hloov pauv. Maj mam yaj hauv dilute hydrochloric acid thiab sulfuric acid, yaj hauv nitric acid

-

Ferro Vanadium

Ferrovanadium yog ib qho hlau alloy tau los ntawm kev txo cov vanadium pentoxide hauv lub cub hluav taws xob nrog cov pa roj carbon, thiab kuj tuaj yeem tau los ntawm kev txo cov vanadium pentoxide los ntawm lub cub hluav taws xob silicon thermal method.

-

HSG Ferro Tungsten nqe rau kev muag khoom ferro wolfram FeW 70% 80% pob

Ferro Tungsten yog npaj los ntawm wolframite los ntawm kev txo cov pa roj carbon hauv lub cub hluav taws xob. Nws feem ntau yog siv ua cov khoom siv ntxiv rau cov hlau tungsten uas muaj cov hlau sib xyaw (xws li cov hlau ceev ceev). Muaj peb hom ferrotungsten tsim tawm hauv Suav teb, suav nrog w701, W702 thiab w65, nrog cov ntsiab lus tungsten ntawm kwv yees li 65 ~ 70%. Vim yog qhov chaw yaj siab, nws tsis tuaj yeem ntws tawm ntawm cov kua, yog li nws yog tsim los ntawm txoj kev caking lossis txoj kev rho tawm hlau.

-

Tuam Tshoj Ferro Molybdenum Hoobkas Khoom Zoo Qis Carbon Femo Femo60 Ferro Molybdenum Nqe

Ferro Molybdenum70 feem ntau yog siv los ntxiv molybdenum rau hauv hlau hauv kev ua hlau. Molybdenum yog sib xyaw nrog lwm cov khoom sib xyaw kom siv dav los ua hlau tsis xeb, hlau tiv taus cua sov, hlau tiv taus kua qaub thiab hlau cuab yeej. Thiab nws kuj tseem siv los tsim cov hlau uas muaj cov khoom tshwj xeeb. Kev ntxiv molybdenum rau hlau casting tuaj yeem txhim kho lub zog thiab kev tiv taus kev sib txhuam.

-

Molybdenum seem

Kwv yees li 60% ntawm Mo seem yog siv los tsim cov hlau tsis xeb thiab cov hlau tsim kho vaj tse. Cov seem yog siv los tsim cov hlau siv ua cov cuab yeej sib xyaw, cov hlau sib xyaw super, cov hlau ceev ceev, hlau cam khwb cia thiab cov tshuaj lom neeg.

Cov hlau thiab cov hlau sib xyaw ua ke - qhov chaw ntawm cov molybdenum rov ua dua tshiab

-

Niobium Block

Khoom npe: niobium ingot / thaiv

Khoom siv: RO4200-1, RO4210-2

Kev Huv Si: >= 99.9% lossis 99.95%

Loj: raws li xav tau

Qhov Ceev: 8.57 g/cm3

Melting Point: 2468 ° C

Kub taw tes: 4742 ° C

Tshuab: Electron Beam ingot cub tawg

-

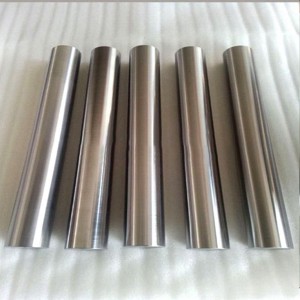

Kev Ntshiab Siab Thiab Kub Siab Alloy Ntxiv Niobium Hlau Nqe Niobium Bar Niobium Ingots

Niobium bar yog sintered los ntawm Nb2O5 hmoov, ib yam khoom semi-finished uas yog siv rau melting niobium ingot, lossis ua ib qho alloy additive rau steel lossis superalloy ntau lawm. Peb cov niobium bar yog carbonized thiab sintered ob zaug. Bar yog ntom thiab cov pa phem tsawg. Peb muab daim ntawv qhia txog kev tshuaj xyuas suav nrog C, N, H, O thiab lwm yam ntsiab lus uas cov neeg siv khoom xav tau. Dhau li ntawm tantalum bar, peb kuj tuaj yeem muab lwm yam khoom tantalum milled thiab cov khoom tsim raws li cov neeg siv khoom xav tau.

-

Astm B392 r04200 Type1 Nb1 99.95% Niobium Qws Ntshiab Niobium Round Bar Nqe

Niobium thiab niobium alloy bar, cov khoom siv hlau vim nws qhov chaw yaj siab, tiv taus corrosion, ua haujlwm txias thiab lwm yam ntxwv, siv dav hauv tshuaj lom neeg, hluav taws xob, aviation thiab aerospace thiab lwm yam teb. Niobium thiab niobium alloy rods yog siv ua cov ntaub ntawv tsim thiab txhua yam ntawm lub cav aviation rocket nozzle, cov khoom sab hauv ntawm reactor thiab cov khoom pob, tsim cov nitric acid, hydrochloric acid lossis sulfuric acid corrosion tsis kam nyob rau hauv cov xwm txheej ntawm cov khoom tiv taus corrosion.