Niobium Block

Cov Khoom Siv

| yam khoom | Niobium Block |

| Qhov chaw keeb kwm | Tuam Tshoj |

| Lub Npe Hom | HSG |

| Tus Qauv Tooj | NB |

| Daim Ntawv Thov | Lub teeb hluav taws xob |

| Duab | thaiv |

| Khoom siv | Niobium |

| Cov Tshuaj Lom Zem | NB |

| Lub npe khoom | Niobium thaiv |

| Kev dawb huv | 99.95% |

| Xim | Xim av nyiaj |

| Hom | thaiv |

| Loj | Qhov Loj Tshwj Xeeb |

| Kev Lag Luam Tseem Ceeb | Tebchaws Europe Sab Hnub Tuaj |

| Qhov Ceev | 16.65g/cm3 |

| MOQ | 1 Kg |

| Pob khoom | Cov nruas hlau |

| Hom | HSGa |

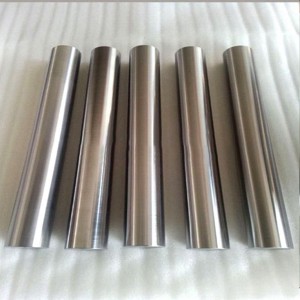

Cov khoom ntawm 99.95% siab purity niobium block

Kev Huv Si: 99.9% Cov Lus Qhia Tshwj Xeeb: 1-15mm, 30-50mm lossis raws li cov neeg siv khoom xav tau. Lub tuam txhab muaj ntau yam kev qhia tshwj xeeb ntawm cov hmoov niobium, cov khoom zoo txhim khu kev qha, tus nqi tsim nyog. Txais tos cov neeg siv khoom tshiab thiab qub los nug. Kev tiv taus kub siab, kev tiv taus corrosion zoo.

Nws yog siv rau hauv kev tsim cov hlau niobium, cov khoom siv superconducting, cov hlau kub siab, lossis cov khoom siv hluav taws xob niobium ingot. Cov lus qhia thiab pob ntawm 99.9% siab purity niobium block

Cov Khoom Piav Qhia

Khoom npe: niobium ingot / thaiv

Khoom siv: RO4200-1, RO4210-2

Kev Huv Si: >= 99.9% lossis 99.95%

Loj: raws li xav tau

Qhov Ceev: 8.57 g/cm3

Melting Point: 2468 ° C

Kub taw tes: 4742 ° C

Tshuab: Electron Beam ingot cub tawg

Nta/Qhov Zoo:

1. Qhov Ceev Tsawg thiab Lub Zog Tshwj Xeeb

2. Kev Tiv Thaiv Kev Sib Tsoo Zoo heev

3. Zoo tiv taus rau qhov cuam tshuam ntawm cua sov

4. Cov ntsiab lus O & C tsawg

Cov ntsiab lus tsis huv

| Fe | Si | Ni | W | Mo | Ti |

| 0.004 | 0.004 | 0.002 | 0.005 | 0.005 | 0.002 |

| Ta | O | C | H | N |

|

| 0.05 | 0.012 | 0.0035 | 0.0012 | 0.003 |

Tus cwj pwm

Melting point: 2468 ℃ Boiling point: 4742 ℃ Ceev: 8.57g / cm³ Qhov hnyav molecular sib piv: 92.9.

Daim ntawv thov ntawm Niobium ingot / thaiv

1. Rau kev tsim cov khoom siv hluav taws xob thiab cov khoom siv nqus tsev fais fab.

2. Rau kev tsim cov khoom cua sov thiab cov khoom siv refractory hauv cov cub tawg kub siab.

3. Rau kev tsim cov khoom siv kuaj mob.

4. Siv ua electrodes hauv kev lag luam tsis tshua muaj av.

5. Siv rau hauv kev tsim riam phom.

6. Siv rau lub raj tiv thaiv thermal ob peb hauv lub cub tawg kub.

7. Siv ua cov khoom ntxiv