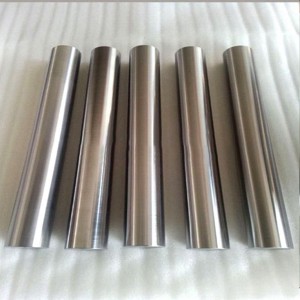

Zoo Thiab Pheej Yig Niobium Nb Hlau 99.95% Niobium Hmoov Rau Kev Tsim HRNB WCM02

Cov Khoom Siv

| yam khoom | tus nqi |

| Qhov chaw keeb kwm | Tuam Tshoj |

| Hebei | |

| Lub Npe Hom | HSG |

| Tus Qauv Tooj | SY-Nb |

| Daim Ntawv Thov | Rau Cov Hom Phiaj Hlau |

| Duab | hmoov |

| Khoom siv | Niobium hmoov |

| Cov Tshuaj Lom Zem | Nb> 99.9% |

| Qhov Loj ntawm Cov Khoom Me Me | Kev Kho Kom Haum |

| Nb | Nb> 99.9% |

| C | C < 500ppm |

| Ni | Ni <300ppm |

| Cr | Cr <10ppm |

| W | W <10ppm |

| N | N <10ppm |

Cov Tshuaj Lom Zem

| HRNb-1 | O | H | C | N | Fe | Si | Ni | Cu |

| 0.20 | 0.005 | 0.05 | 0.04 | 0.01 | 0.005 | 0.005 | 0.005 | |

| Ta | W | Mo | Ti | Mn | Cu | Nb+Ta | ||

| <0.20 | 0.005 | 0.003 | 0.003 | 0.003 | 0.003 | >99 |

| HRNb-2 | O | H | C | N | Fe | Si | Ni | Cu |

| 0.20 | 0.005 | 0.05 | 0.06 | 0.05 | 0.01 | 0.005 | 0.005 | |

| Ta | W | Mo | Ti | Mn | Nb+Ta | |||

| <0.50 | 0.01 | 0.005 | 0.005 | 0.005 | >99 |

| HRNb-3 | O | H | C | P | S | Nb+Ta |

|

|

| 0.50 | 0.01 | 0.08 | 0.01 | 0.01 | >98 |

|

|

Cov Khoom Piav Qhia

Niobium Nb Hmoov Hlau

Niobium yog xim grey hlau, melting point 2468 ℃, boiling point 4742 ℃. Niobium ruaj khov hauv huab cua ntawm chav tsev kub, xim liab tsis nyob hauv cov pa oxygen oxidation kiag li.

Qhov loj ntawm peb cov hmoov Niobium

Qhov loj me me tshaj plaws: 200mesh & 300mesh; qhov loj tshaj plaws: 500mesh

Pacakge

Ntim: Lub raj mis yas hauv lub thawv lossis raws li koj xav tau.

Kev xa khoom qhia: hauv 2-3 hnub tom qab tau txais cov nyiaj them poob haujlwm

Daim Ntawv Thov

1. Niobium yog ib qho khoom siv superconducting tseem ceeb heev los tsim cov capacitor muaj peev xwm siab.

2. Niobium hmoov kuj tseem siv los tsim tantalum.

3. Cov hmoov hlau Niobium ntshiab lossis Niobium Nickel alloy yog siv los ua Nickel, Chrome thiab Iron base high temperature alloy. Cov alloy no yog siv rau cov cav dav hlau, cov cav roj turbine, rocket assembly, lub turbocharger thiab cov khoom siv combustion kub;

4. Los ntawm kev ntxiv 0.001% rau 0.1% Niobium nano hmoov zoo txaus los hloov cov khoom siv kho tshuab ntawm hlau.

5. Vim tias qhov coefficient ntawm thermal expansion ntawm Niobium zoo ib yam li cov khoom siv sintered alumina ceramic ntawm lub teeb arc, Nb nano hmoov tuaj yeem siv ua cov khoom kaw ntawm lub raj arc.