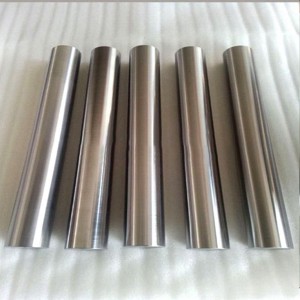

Hoobkas Ncaj Qha Muab Khoom Siv Tshwj Xeeb 99.95% Purity Niobium Sheet Nb Phaj Nqe Ib Kg

Cov Khoom Siv

| Lub npe khoom | Lag luam wholesale siab purity 99.95% Niobium ntawv Niobium phaj Niobium nqe ib kg |

| Kev dawb huv | Nb ≥99.95% |

| Qib | R04200, R04210, R04251, R04261, Nb1, Nb2 |

| Tus Qauv | ASTM B393 |

| Loj | Qhov loj me uas hloov kho |

| Qhov kub yaj | 2468 ℃ |

| Kub taw tes | 4742 ℃ |

Loj Phaj (0.1 ~ 6.0) * (120 ~ 420) * (50 ~ 3000) hli:

| Qhov tuab | Qhov tuab ntawm qhov sib txawv uas tso cai | Dav | Qhov dav ntawm qhov kev hloov pauv uas tso cai | Ntev | |

| Dav> 120 ~ 300 | Dav> 300 | ||||

| 0.1~0.2 | ±0.015 | ±0.02 | >300~420 | ±2.0 | >100 |

| >0.2~0.3 | ±0.02 | ±0.03 | >200~420 | ±2.0 | >100 |

| >0.3~0.5 | ±0.03 | ±0.04 | >200~420 | ±2.0 | 50 ~ 3000 |

| >0.5~0.8 | ±0.04 | ±0.06 | >200~420 | ±2.0 (±5.0) | 50 ~ 3000 |

| >0.8~1.0 | ±0.06 | ±0.08 | >200~420 | ±2.0 (±5.0) | 50 ~ 3000 |

| >1.0~1.5 | ±0.08 | ±0.10 | >200~420 | ±3.0 (±5.0) | 50 ~ 3000 |

| >1.5~2.0 | ±0.12 | ±0.14 | >200~420 | ±3.0 (±5.0) | 50 ~ 3000 |

| >2.0~3.0 | ±0.16 | ±0.18 | >200~420 | ±5.0 | 50 ~ 3000 |

| >3.0~4.0 | ±0.18 | ±0.20 | >200~420 | ±5.0 | 50 ~ 3000 |

| >4.0~6.0 | ±0.20 | ±0.24 | >200~420 | ±5.0 | 50 ~ 3000 |

Kev Xav Tau Txog Kev Kho Tshuab (Kev Kho Mob Annealed):

| Qib | Lub zog tensile δbpsi (MPa), ≥ | Lub zog tawm los δ0.2, psi (MPa), ≥ | Kev ntev hauv 1 "/ 2" gage ntev,%, ≥ |

| RO4200-1RO4210-2 | 18000 (125) | 12000 (85) | 25 |

| Cov tshuaj lom neeg muaj pes tsawg leeg (%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| Nb1 | Cov seem seem | 0.004 | 0.002 | 0.002 | 0.004 | 0.004 | 0.002 | 0.07 | 0.015 | 0.005 | 0.0015 | 0.003 |

| Nb2 | Cov seem seem | 0.02 | 0.02 | 0.005 | 0.02 | 0.02 | 0.005 | 0.15 | 0.03 | 0.01 | 0.0015 | 0.01 |

Qhov zoo

Qhov Ceev Tsawg thiab Lub Zog Tshwj Xeeb Siab

♦ Kev Tiv Thaiv Kev Xeb Zoo heev

♦ Zoo tiv taus rau qhov cuam tshuam ntawm cua sov

♦ Tsis muaj hlau nplaum thiab tsis muaj tshuaj lom

♦ Lub ntsiab lus yaj siab, zoo tiv thaiv xeb, zoo heev super-conduction thiab lwm yam ntxwv tshwj xeeb.

Daim Ntawv Thov

♦ Kev lag luam hluav taws xob, Chemistry, Electronical, Kev lag luam tshuaj.

♦ Hlau, Ceramics, Electronics, nuclear energy industries thiab superconductor technology.

♦ Cov khoom siv hlau nplaum zoo heev, cov hlau nplaum uas muaj cov khoom sib xyaw thiab cov neeg ua haujlwm sib xyaw.

♦ Siv dav hauv kev tsim ntau hom hlau alloy, kub alloy, iav kho qhov muag, cov cuab yeej txiav, cov ntaub ntawv superconducting thiab lwm yam lag luam.