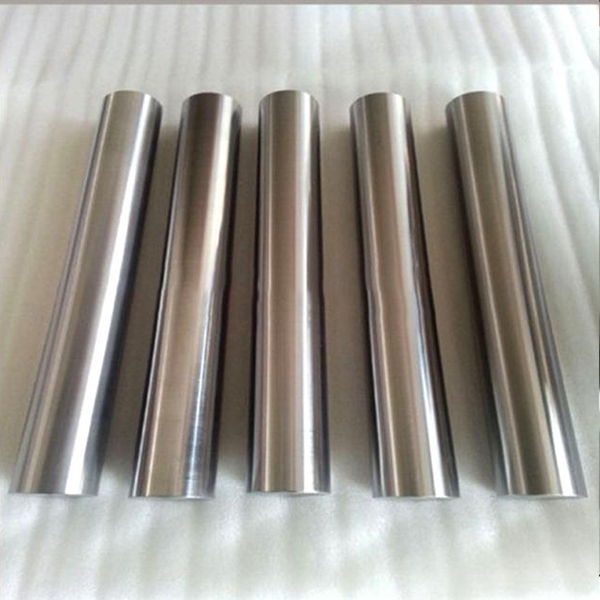

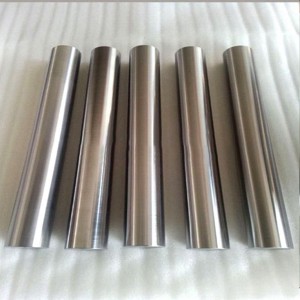

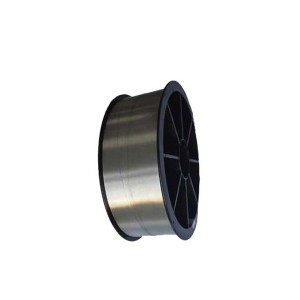

Astm B392 r04200 Type1 Nb1 99.95% Niobium Qws Ntshiab Niobium Round Bar Nqe

Cov Khoom Siv

| Lub npe khoom | ASTM B392 B393 Siab Purity Niobium Qws Niobium Bar nrog Tus Nqi Zoo Tshaj Plaws |

| Kev dawb huv | Nb ≥99.95% |

| Qib | R04200, R04210, R04251, R04261, Nb1, Nb2 |

| Tus Qauv | ASTM B392 |

| Loj | Qhov loj me uas hloov kho |

| Qhov kub yaj | 2468 degree centigrade |

| Kub taw tes | 4742 degree centigrade |

| Qhov zoo | ♦ Qhov Ceev Tsawg thiab Lub Zog Tshwj Xeeb Siab ♦ Kev Tiv Thaiv Kev Sib Tsoo Zoo heev |

| ♦ Zoo tiv taus rau qhov cuam tshuam ntawm cua sov | |

| ♦ Tsis muaj hlau nplaum thiab tsis muaj tshuaj lom | |

| ♦ Lub ntsiab lus yaj siab, zoo tiv thaiv xeb, zoo heev super-conduction thiab lwm yam ntxwv tshwj xeeb. |

| Cov tshuaj lom neeg muaj pes tsawg leeg (%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| Nb1 | Cov seem seem | 0.004 | 0.002 | 0.002 | 0.004 | 0.004 | 0.002 | 0.07 | 0.015 | 0.005 | 0.0015 | 0.003 |

| Nb2 | Cov seem seem | 0.02 | 0.02 | 0.005 | 0.02 | 0.02 | 0.005 | 0.15 | 0.03 | 0.01 | 0.0015 | 0.01 |

Kev kam rau siab ntawm qhov ntev

| Txoj kab uas hla(hli) | Kev kam rau siab ntawm txoj kab uas hla (hli) | Ntev (hli) | Kev kam rau siab ntawm qhov ntev (hli) |

| 3.0-4.5 | ±0.05 | 200-1500 | +5 |

| >4.5-6.5 | ±0.10 | 200-1500 | |

| >6.5-10.0 | ±0.15 | 200-1500 | |

| >10-16 | ±0.20 | 200-2000 | |

| >16-18 | ±1.0 | 200-2000 | |

| >18-25 | ±1.5 | 200-2000 | |

| >25-40 | ±2.0 | 200-2000 | |

| >40-50 | ±2.50 | 200-2000 | |

| >50-65 | ±3.00 | 200-2000 | |

| >65-150 | ±4.00 | 200-1000 |

Kev Xav Tau Kho Tshuab (Annealed mob)

| Qib | Lub zog tensile δbpsi (MPa), ≥ | Lub zog tawm los δ0.2, psi (MPa), ≥ | Kev ntev hauv 1 "/ 2" gage ntev,%, ≥ |

| RO4200-1 RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Daim Ntawv Thov

♦ Kev lag luam hluav taws xob, Chemistry, Electronical, Kev lag luam tshuaj.

♦ Hlau, Ceramics, Electronics, nuclear energy industries thiab superconductor technology.

♦ Cov khoom siv hlau nplaum zoo heev, cov hlau nplaum uas muaj cov khoom sib xyaw thiab cov neeg ua haujlwm sib xyaw.

♦ Siv dav hauv kev tsim ntau hom hlau alloy, kub alloy, iav kho qhov muag, cov cuab yeej txiav, cov ntaub ntawv superconducting thiab lwm yam lag luam.

Sau koj cov lus ntawm no thiab xa tuaj rau peb