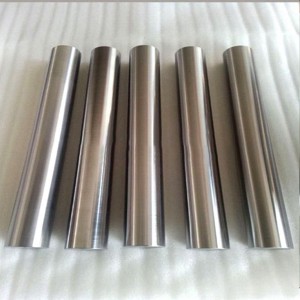

Raws li Cov Khoom Sau Ua Ke Polished Surface Nb Ntshiab Niobium Hlau Niobium Cube Niobium Ingot

Cov Khoom Siv

| Lub Npe Khoom | Niobium ntshiab |

| Khoom siv | Niobium ntshiab thiab niobium alloy |

| Qhov Loj | Raws li koj qhov kev thov |

| Qib | RO4200.RO4210,R04251,R04261 |

| Txheej Txheem | Txias dov, Kub dov, Extruded |

| Yam ntxwv | Melting point: 2468 ℃ Boiling point: 4744 ℃ |

| Daim Ntawv Thov | Siv dav hauv tshuaj lom neeg, khoom siv hluav taws xob, aviation thiab aerospace teb |

| Cov yam ntxwv ntawm cov khoom | Kev Tiv Thaiv Kev Sib Tsoo Zoo heev Zoo tiv taus qhov cuam tshuam ntawm cua sov |

Niobium Qib & muaj pes tsawg leeg

| Qib | ||||

| RO4200 | RO4210 | RO4251 | RO4261 | |

| Zr | 0.02 | 0.02 | 0.8~1.2 | 0.8~1.2 |

| Ta | 0.1 | 0.2 | 0.1 | 0.5 |

| Fe | 0.005 | 0.01 | 0.005 | 0.01 |

| Si | 0.005 | 0.005 | 0.005 | 0.005 |

| W | 0.03 | 0.05 | 0.03 | 0.05 |

| Ni | 0.005 | 0.005 | 0.005 | 0.005 |

| Mo | 0.010 | 0.010 | 0.010 | 0.05 |

| Hf | 0.02 | 0.02 | 0.02 | 0.02 |

| B | 0.0002 | - | 0.0002 | - |

| Al | 0.002 | 0.005 | 0.002 | 0.005 |

| Be | 0.005 | - | 0.005 | - |

| Cr | 0.002 | - | 0.002 | - |

| Co | 0.002 | - | 0.002 | - |

| Nb | Qhov Nyiaj Tshuav | Qhov Nyiaj Tshuav | Qhov Nyiaj Tshuav | Qhov Nyiaj Tshuav |

Cov kev cai kho tshuab (mob annealed)

| Qib | Lub zog tensile δb psi (MPa), ≥ | Lub zog tawm los δ0.2, psi (MPa), ≥ | Kev ntev hauv 1 "/ 2" ntev ntsuas,%, ≥ |

| RO4200-1 RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Tag nrho cov khoom siv Niobium muaj

| Lub npe khoom | Qib | Tus Qauv |

| Niobium ingot | RO4200, RO4210, RO4251, R04261 | ASTM B392, 393, 394 ASTM B708, 365, 521 |

| Niobium bar | ||

| Niobium raj | ||

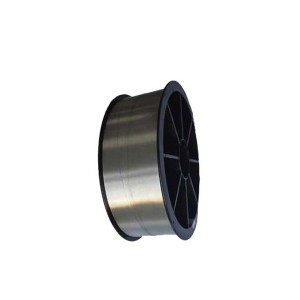

| Niobium hlau | ||

| Daim ntawv Niobium | ||

| Niobium crucible | ||

| Lub hom phiaj Niobium | ||

| Cov khoom Niobium |

Feature

1. Qib: Nb1, Nb-Ti, RO4200, RO4210

2. Loj: Dia 1 hli min.

3. Kev Huv Si: 99.95%

4. Daim Ntawv Pov Thawj: ISO9001: 2008, ISO14001: 2004, CE

5. Cov duab: pas nrig, bar, phaj, ntawv, ntawv ci, raj, hlau, crucible, thiab lwm yam.

6. Cov Qauv: ASTM B392, 393, 394...

7. Daim Ntawv Thov: Cov ntaub ntawv semiconductor, txheej nqus tsev, cov tais sintering thiab cov nkoj, cov ntawv thov tshuaj lom neeg tshwj xeeb.

8. Khoom Feature: High melting point, high-density, high temperature oxidation resistance, long service, resistant to corrosion.

Daim Ntawv Thov

1. Kev lag luam hluav taws xob Chemistry, electronical, Pharmaceu kev lag luam.

2. Rau cov hlau, ceramics, electronics, nuclear energy industries thiab superconductor technology;

3. Rau cov khoom siv super conductous, metled cast ingots thiab alloying agents.

4. Siv dav hauv kev tsim ntau hom hlau alloy, kub alloy, iav optical, txiav cov cuab yeej, hluav taws xob thiab cov ntaub ntawv superconducting thiab lwm yam lag luam.